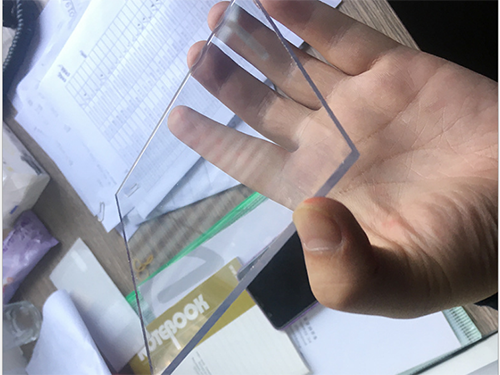

PET sheet is a new type of plastic product developed in recent years. This is a thermoplastic ring-wrapped plastic product. It is odorless and tasteless after burning, and does not produce toxic gas. High transparency, no water ripple, no crystallization point, no directionality, no whiteness, strong oil resistance and chemical resistance, good toughness and rigidity, good impact resistance (low temperature impact resistance is also good, 20% higher than pvc about). It has a good blocking property, high transparency, high impact resistance, good cold resistance, and is not easy to be broken; high strength, not afraid of friction, excellent material performance, special PET sheet also has its unique properties: low temperature heat sealing, resistance to friction High temperature, anti-mirror electricity.

PET advantages:

1. Bending resistance, good performance, high impact strength, several times that of ordinary materials.

2. Not easy to react with other chemicals.

3. Water, liquid, edible oil and gas are easily blocked and not easily penetrated.

4. Transparent color, anti-ultraviolet penetration.

5. No questions asked, non-toxic, can be directly used for food packaging. The product has good transparency, small specific gravity, good surface gloss, bright color, few crystal points and water ripples, and has the characteristics of toughness, impact resistance, chemical resistance and easy processing.

Application areas:

1. In terms of plastic films: such as food, medicine, and sterile packaging films; as well as some precision instruments, electronic product packaging, packaging films for large machinery, etc.

2. Plastic bottle packaging: such as bottled water, mineral water, beverage bottles, daily oil, condiment bottles, daily chemical products, etc.

3. Precision instruments for home appliances: such as electronic link lines, integrated circuits, various switch casings, control open casings, TV accessories, etc.

4. Machinery and equipment in the chemical industry: machine parts, chains, frames, etc.

The production process of PET sheet is more complicated. It is produced through a series of compression and polymerization processes using high precision machinery. The plastic we generally see is a translucent substance, but the transparency of this material can be changed in real time according to its specific requirements, and due to its own ductility and plasticity, it can also be placed in our home or office as a At the same time, even if the service life is reached, when it needs to be recycled, even if it is burned, it will not produce any polluting gas, and the harm to the environment is minimal.

It is also possible to make pet into a foam material at the same time through a special compression method, so that we will fill a large amount of air between the two materials, and since this material is formed, its molecular structure becomes very stable, so Even if it is hit or squeezed by gravity, it will not be easily deformed, so we generally use it in the express industry to respond quickly. It plays a very good role in protecting the transportation of goods. And it also cuts, and it's very tough, so we just need a normal knife to get it into any shape we want.