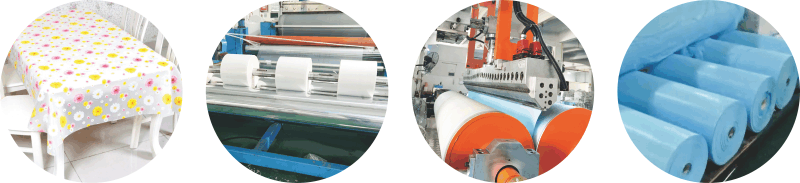

Haitao Machinery's cast film extruder is a piece of equipment used to produce films. Simply put, it works by squeezing molten plastic or other flowable material through a die to form a thin film. The process is similar to rolling dough into pancakes, except here molten plastic is used instead of dough.

The entire process usually includes the following steps:

Melting stage: Plastic pellets or other raw materials are heated to melt into a flowing liquid.

Extrusion stage: The molten plastic is squeezed out through an extruder, which resembles a large screw.

Casting stage: The extruded plastic is sent to a casting film head, through which it is extruded to form a film.

Cooling stage: The film is passed through a cooling device, usually a series of rollers or cooling fans, where it is rapidly cooled and solidified.

This film is commonly used in packaging, construction materials, agricultural mulches and more. Cast film extruders are an efficient production process that can produce large-area, uniform-thickness films.

Cast film extruders have some notable features that make them widely used in film production. Here are some of its key features:

Efficient Production: Cast film extruders are able to continuously produce films at relatively high speeds, making them an efficient production process.

Multi-material applicability: This extruder is not only suitable for various types of plastics, but can also be used to produce films of other materials, such as paper, metal foil, etc., with strong material applicability.

Adjustable film width: The extruder can adjust the width of the film to meet the needs of different applications, thereby increasing production flexibility.

Uniform Film Thickness: Cast film extruders produce uniform films, ensuring consistent thickness across the entire film surface.

Simple operation: Compared with some complex manufacturing processes, the operation of the cast film extruder is relatively simple, making it easy for production management and operation.

Wide application: Due to its high efficiency and versatility, cast film extruders are widely used in packaging, construction, agriculture and other fields to meet the needs of different industries for film products.

Cost-effectiveness: Compared with some other film manufacturing processes, cast film extruders have lower production costs, helping to improve the competitiveness of products.